What is inventory optimization

And how should you take advantage of it

Inventory optimization is a much-used phrase, but what exactly is it, how do you achieve it and do you in fact even need it? As our mission as a company is to help organisations get value from inventory optimization, this is a topic very close to our heart.

In this article we consider inventory optimization to be the application of mathematical techniques to define ideal inventory levels. Such theoretical models are not easy to apply in practice. The idea that a piece of software can allow you to optimize your inventories simply and automatically is attractive but at present far from possible.

We believe that the biggest value to be had from inventory optimization techniques is in showing you how much better your inventories could be, while the correct interpretation and application of that information is likely to require changes to how you manage your inventory.

The benefits of overcoming these challenges are substantial. Inventory optimization allows you to free up working capital, reduce shortages and obsolescence, reduce your environmental footprint and increase flow through your supply chain, usually by significant amounts.

In this article we consider inventory optimization to be the application of mathematical techniques to define ideal inventory levels. Such theoretical models are not easy to apply in practice. The idea that a piece of software can allow you to optimize your inventories simply and automatically is attractive but at present far from possible.

We believe that the biggest value to be had from inventory optimization techniques is in showing you how much better your inventories could be, while the correct interpretation and application of that information is likely to require changes to how you manage your inventory.

The benefits of overcoming these challenges are substantial. Inventory optimization allows you to free up working capital, reduce shortages and obsolescence, reduce your environmental footprint and increase flow through your supply chain, usually by significant amounts.

What is inventory optimization?

You will often see any improvement to inventory management described as inventory optimization, but this is not strictly speaking accurate.

In mathematics, optimization means selecting the best option from a set of alternatives. When talking about inventory, this comes down to determining the best amount of inventory to hold to meet your objectives. Inventory optimization mathematically seeks to find the sweet spot between having too much and not enough.

This is a simple concept to grasp in principle, but not to apply in practise. In order to calculate an optimum level mathematically, you need to factor in a number of different considerations, some of which are themselves difficult to quantify.

Let’s say that you want to optimize on purely economic principles – what will make you the most profit? To do this you need to be able to quantify, on the one hand, the true holding cost of inventory and, on the other hand, the cost of shortages, which might include backorder costs, expediting costs, the cost of lost sales and lost market share, even the cost of damage to your brand. Noting that these costs are entwined with each other. It’s not that this is impossible to do, but it is laborious and somewhat imprecise.

In fact, it would be fair to say that few people, if any, actually try to calculate this. Instead, normal practice is to set a target service level, either implicitly or explicitly, and then try to minimize inventories while staying at or above that service level. This is a good, pragmatic move, that ties down one of the more difficult parameters to set. However, even with a pre-defined target service level, there is still a lot of work to do to calculate optimum inventory levels.

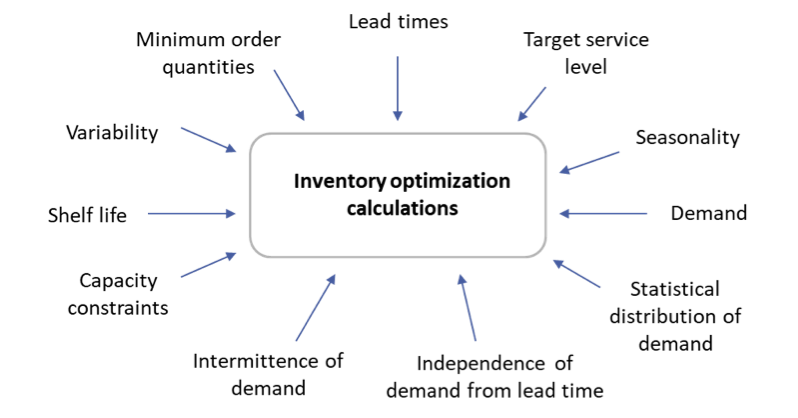

When it comes to improving inventories, we like to differentiate between optimizing, which involves working with the givens, and improvements based on changing the givens. What are the givens? They are the parameters you need as inputs to your inventory optimization calculations. We have already looked at target service level as a given, but this is just one of a range of such parameters.

In mathematics, optimization means selecting the best option from a set of alternatives. When talking about inventory, this comes down to determining the best amount of inventory to hold to meet your objectives. Inventory optimization mathematically seeks to find the sweet spot between having too much and not enough.

This is a simple concept to grasp in principle, but not to apply in practise. In order to calculate an optimum level mathematically, you need to factor in a number of different considerations, some of which are themselves difficult to quantify.

Let’s say that you want to optimize on purely economic principles – what will make you the most profit? To do this you need to be able to quantify, on the one hand, the true holding cost of inventory and, on the other hand, the cost of shortages, which might include backorder costs, expediting costs, the cost of lost sales and lost market share, even the cost of damage to your brand. Noting that these costs are entwined with each other. It’s not that this is impossible to do, but it is laborious and somewhat imprecise.

In fact, it would be fair to say that few people, if any, actually try to calculate this. Instead, normal practice is to set a target service level, either implicitly or explicitly, and then try to minimize inventories while staying at or above that service level. This is a good, pragmatic move, that ties down one of the more difficult parameters to set. However, even with a pre-defined target service level, there is still a lot of work to do to calculate optimum inventory levels.

When it comes to improving inventories, we like to differentiate between optimizing, which involves working with the givens, and improvements based on changing the givens. What are the givens? They are the parameters you need as inputs to your inventory optimization calculations. We have already looked at target service level as a given, but this is just one of a range of such parameters.

Figure 1: The givens, of which the most common are shown here, all influence inventory optimization calculations, and are all subject to change themselves.

When you work with the givens, you don’t challenge them, you accept them as fixed parameters and then try to optimize your inventory levels on that basis. Which is not to say that the givens can’t be improved, but you strictly speaking need to have such parameters defined to be able even to attempt an optimization calculation.

How can you optimize your inventories?

Inventory optimization comes down to defining two things for each item: the optimal order quantity/batch size (Q) and the optimal safety stock (SS), noting that the latter might be zero or even negative. But there is no one way to do this for all items you stock, since the method chosen will itself vary depending on a number of factors. Let us start by taking a couple of simple examples.

- You have a product that is made to order. Whenever a customer orders one, you have 10 weeks to make it. It takes one week to make and 4 weeks to source the parts. Everything you need is at or above your minimum order quantities (MOQ’s) and you have no inbound supply variability or capacity constraints.

- You have a product that is made to stock. Demand is relatively stable, with a limited amount of variability, as is supply. You check inventory levels of finished goods continuously; you schedule production to avoid stock outs and you try to maintain raw materials inventory to be able to produce when needed.

Note that if anything in bold changes, the change will need to be factored into your optimization calculation, as will many of the other factors shown in Figure 1 above.

Different types of inventory require not just different optimization calculations, but also different planning methodologies.

For the first example above, we can consider a deterministic planning model. This is appropriate when you know with a high degree of certainty what demand is going to be, or at least that it is going to be significantly different to the past. In this instance, your order and batch sizes can be set to exactly what is required and in principle you shouldn’t need safety stock, although you might need to have some safety stock to protect against variation in supply, such as late deliveries or quality problems in production.

For the second example, we can consider a replenishment model. This is appropriate for make-to-stock finished goods and buy-to-stock raw materials where demand is not too intermittent but displays variability. In this case, the EOQ model or one of its variants should be used to calculate optimal order/batch size. Safety stock can be calculated using the target service level, the standard deviations of demand and lead time, and the lead time itself.

However, this replenishment model, which is based on probably the most widely known text-book set of equations, has important sensitivities. The most commonly found version of the safety stock equation, for instance, assumes that demand is normally distributed, that average demand does not vary, and it also breaks down when the variability is very high. You will sometimes find people saying that the equations “don’t work”, but this is often just their understanding of the equations running into some of these barriers which they either don’t understand or at any rate don’t know how to work around.

Note that different models might work best at different points in your supply chain. For instance, you might, depending on your exact circumstances, choose a replenishment model for finished goods and a deterministic model for raw materials. To really optimize your inventories, you are likely to need to employ different strategies for different types of inventory.

And these two examples are far from representing the only types of stock you might carry. For instance, you may have make-to-order items where the customer promise time is shorter than the total supply lead time. You may have spare parts with highly sporadic demand but which need to be available on demand. And so on. Each different type of inventory needs an appropriate optimization approach.

In order to fully optimize your inventories, all of the factors above need to be taken into consideration for every single item that you stock. And so far, we’re just talking about mathematical optimization. In addition – and no less a challenge – you have to consider what processes, systems and people are in place and how they would need to change in order to deliver and maintain the optimization.

In our experience, the biggest gap is often in the people themselves and how they are used to working. The knowledge of optimization techniques and how to take advantage of them is a rare commodity amongst material planners, whereas data scientists do not necessarily have the requisite understanding of the practicalities of the business to enable practical application of their models. Technology is sometimes seen as a way around this – remove people from the equation as far as possible – but we are a long way from this being a satisfactory solution yet.

Different types of inventory require not just different optimization calculations, but also different planning methodologies.

For the first example above, we can consider a deterministic planning model. This is appropriate when you know with a high degree of certainty what demand is going to be, or at least that it is going to be significantly different to the past. In this instance, your order and batch sizes can be set to exactly what is required and in principle you shouldn’t need safety stock, although you might need to have some safety stock to protect against variation in supply, such as late deliveries or quality problems in production.

For the second example, we can consider a replenishment model. This is appropriate for make-to-stock finished goods and buy-to-stock raw materials where demand is not too intermittent but displays variability. In this case, the EOQ model or one of its variants should be used to calculate optimal order/batch size. Safety stock can be calculated using the target service level, the standard deviations of demand and lead time, and the lead time itself.

However, this replenishment model, which is based on probably the most widely known text-book set of equations, has important sensitivities. The most commonly found version of the safety stock equation, for instance, assumes that demand is normally distributed, that average demand does not vary, and it also breaks down when the variability is very high. You will sometimes find people saying that the equations “don’t work”, but this is often just their understanding of the equations running into some of these barriers which they either don’t understand or at any rate don’t know how to work around.

Note that different models might work best at different points in your supply chain. For instance, you might, depending on your exact circumstances, choose a replenishment model for finished goods and a deterministic model for raw materials. To really optimize your inventories, you are likely to need to employ different strategies for different types of inventory.

And these two examples are far from representing the only types of stock you might carry. For instance, you may have make-to-order items where the customer promise time is shorter than the total supply lead time. You may have spare parts with highly sporadic demand but which need to be available on demand. And so on. Each different type of inventory needs an appropriate optimization approach.

In order to fully optimize your inventories, all of the factors above need to be taken into consideration for every single item that you stock. And so far, we’re just talking about mathematical optimization. In addition – and no less a challenge – you have to consider what processes, systems and people are in place and how they would need to change in order to deliver and maintain the optimization.

In our experience, the biggest gap is often in the people themselves and how they are used to working. The knowledge of optimization techniques and how to take advantage of them is a rare commodity amongst material planners, whereas data scientists do not necessarily have the requisite understanding of the practicalities of the business to enable practical application of their models. Technology is sometimes seen as a way around this – remove people from the equation as far as possible – but we are a long way from this being a satisfactory solution yet.

Inventory optimization software

There are a number of software solutions on the market, including ERP systems themselves, that aim to help you achieve inventory optimization. Whichever one you choose, if any, it should be thought of as part of the solution rather than the whole solution. These tools are very sensitive to the input parameters, make different assumptions and have varying degrees of ease of use. Most practitioners find that their tools work well for some types of inventory but not for others. We believe that supply chain planners need to understand at least in principle how their tools work and what their limitations are.

One of the issues with optimization technology, and optimization itself, is its precision. Because it is a mathematical calculation, it will produce an embarrassingly precise value. Because so many of the parameters used to calculate optimal levels are approximate, one should naturally be cautious of taking the tools too precisely. Given the precision of the calculation and the imprecision of many of the critical parameters, automation – letting the tools do the planning with little or no human intervention - is risky.

One of the most important principles in applying inventory optimization is incremental progress. Human brains are much better at applying caution to new approaches than machines and are an essential input to moving towards optimization. If an optimization tool or equation tells you that you can decrease inventory for an item by 20%, a sensible human approach would be to try decreasing it by 10% first and seeing what happens, but optimization tools don’t make this easy. Only once techniques have been tested and are trusted should they be fully automated and, even then, verified on a regular basis.

However, technology is an important part of the solution. As is hopefully evident from this white paper, even calculating optimal levels is complex, labour-intensive and error-prone. Especially where large numbers of items are being managed, it is essential to take advantage of technology to be able to get anywhere close to inventory optimization. Just be wary of software that appears to offer a silver bullet…

One of the issues with optimization technology, and optimization itself, is its precision. Because it is a mathematical calculation, it will produce an embarrassingly precise value. Because so many of the parameters used to calculate optimal levels are approximate, one should naturally be cautious of taking the tools too precisely. Given the precision of the calculation and the imprecision of many of the critical parameters, automation – letting the tools do the planning with little or no human intervention - is risky.

One of the most important principles in applying inventory optimization is incremental progress. Human brains are much better at applying caution to new approaches than machines and are an essential input to moving towards optimization. If an optimization tool or equation tells you that you can decrease inventory for an item by 20%, a sensible human approach would be to try decreasing it by 10% first and seeing what happens, but optimization tools don’t make this easy. Only once techniques have been tested and are trusted should they be fully automated and, even then, verified on a regular basis.

However, technology is an important part of the solution. As is hopefully evident from this white paper, even calculating optimal levels is complex, labour-intensive and error-prone. Especially where large numbers of items are being managed, it is essential to take advantage of technology to be able to get anywhere close to inventory optimization. Just be wary of software that appears to offer a silver bullet…

Do you need inventory optimization?

From the brief summary above, it should be evident that inventory optimization is not simple. In fact, it would be closer to the truth to call it impossible than to call it simple, but this is not an all or nothing situation. Given the complexities outlined, as well as the fact that your optimal inventory levels are constantly changing, it should be admitted from the start that fully optimized inventory is not an achievable goal. But the application of optimization techniques is incredibly valuable. You don’t have to win an Olympic gold medal to get value from learning how to swim. Moreover, many of the biggest benefits from inventory optimization come from the first steps.

In the absence of inventory optimization, inventory management is flying blind. You are searching for the sweet spot between too little and too much inventory without knowing where that sweet spot is. Think of it as trying to find a black mouse in a completely dark room. With optimization techniques, you are switching the light on. It may still be difficult to catch the mouse, but at least you can get closer to it because you can see where it is.

It is of course possible to manage your inventories without trying to optimize them, and especially in times of abundant cheap cash this is what many organisations choose to do. But without the analytics of inventory optimization you have no real way of knowing how well you’re doing. Or rather, your view becomes lopsided. Your service level performance will tell you if you have enough, but what is telling you if you have too much? Top-down aggregate measures like cover, inventory turns or DIO give you ratios that will tell you whether you’re getting leaner or not over time, and can be used for quick benchmarking exercises, but strictly speaking tell you nothing about how much you ideally should have.

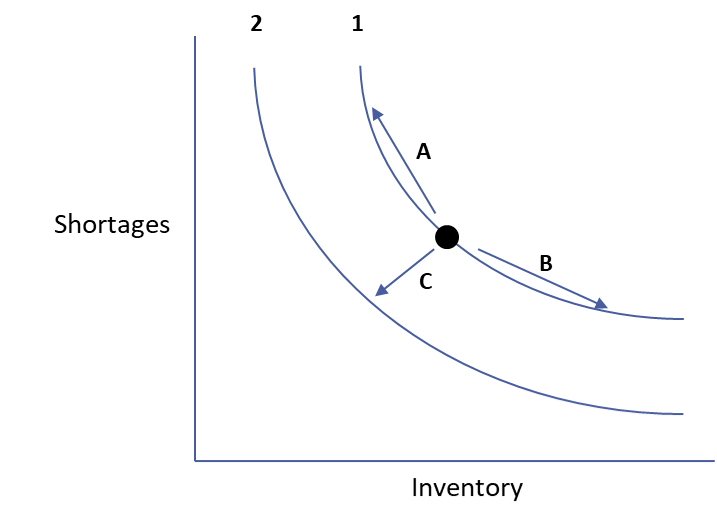

Where organisations do not use optimization techniques, there is a strong tendency to apply “one size fits all” approaches to different types of inventory: for instance, setting target safety stock levels for all raw materials at 2 weeks’ average demand. This could only possibly be optimal if all of your raw materials had identical variability of demand and supply as well as identical lead times. This one size fits all approach means there is a strong correlation between shortages and inventory levels long before you reach an optimized level. Because inventory optimization by necessity works at an individual item level, it allows you in aggregate to reduce inventories and shortages simultaneously.

In the absence of inventory optimization, inventory management is flying blind. You are searching for the sweet spot between too little and too much inventory without knowing where that sweet spot is. Think of it as trying to find a black mouse in a completely dark room. With optimization techniques, you are switching the light on. It may still be difficult to catch the mouse, but at least you can get closer to it because you can see where it is.

It is of course possible to manage your inventories without trying to optimize them, and especially in times of abundant cheap cash this is what many organisations choose to do. But without the analytics of inventory optimization you have no real way of knowing how well you’re doing. Or rather, your view becomes lopsided. Your service level performance will tell you if you have enough, but what is telling you if you have too much? Top-down aggregate measures like cover, inventory turns or DIO give you ratios that will tell you whether you’re getting leaner or not over time, and can be used for quick benchmarking exercises, but strictly speaking tell you nothing about how much you ideally should have.

Where organisations do not use optimization techniques, there is a strong tendency to apply “one size fits all” approaches to different types of inventory: for instance, setting target safety stock levels for all raw materials at 2 weeks’ average demand. This could only possibly be optimal if all of your raw materials had identical variability of demand and supply as well as identical lead times. This one size fits all approach means there is a strong correlation between shortages and inventory levels long before you reach an optimized level. Because inventory optimization by necessity works at an individual item level, it allows you in aggregate to reduce inventories and shortages simultaneously.

Figure 2: Without inventory optimization, inventory management meets a natural barrier (1), where you are choosing between reducing inventory at the expense of shortages (A) or reducing shortages at the expense of inventory (B). Inventory optimization allows you to move the whole barrier (C) and thereby reduce inventory and shortages simultaneously. Note that the new barrier (2) also represents a pay-off between shortages and inventory, but at a better level. Changing the givens can also move the barrier.

From our own empirical experience of working with multiple organisations, it is normally the case that inventory optimization alone (so taking the givens as given) allows net inventory reductions of 20-50% while maintaining or improving service levels. This improvement takes time and effort to achieve, but double-digit improvements are normally achievable in the first year. We can think of no other option that will deliver such a large improvement so quickly in such a risk-free fashion.

How do you take advantage of inventory optimization?

The good news is that not all of the technical problems need to be solved at once and that some of the biggest benefits come from the simplest steps.

To take advantage of inventory optimization you need two things. Firstly, the ability to run the optimization calculations. Secondly, and no less importantly, the ability to operationalize the findings of your analytics. You will only sustainably improve inventory levels if your organisation can use the insights generated by the analytics in its day to day work.

The biggest value in inventory optimization analytics comes from the visibility it gives you into where the biggest opportunities for improvement are. It highlights things that are not necessarily obvious or intuitive. In the first instance, a calculation using a number of approximations is normally good enough. Once this is well understood, you can go further and seek to remove or refine the input approximations one at a time, noting that you will never remove all of them entirely.

Because the analytical challenge is high, specialist skills are required to do it properly. But those skills are not necessarily the same ones required to make changes to how your business actually works. Too much emphasis on analytics, or a siloed mentality, can leave a large gap between theory and practice. The analytics itself is only one part of the picture. In addition, you need to build the people, processes and systems to take advantage of it.

Inventory optimization is not something you can implement and then forget about. Rather, it is an ongoing process which needs constant attention. All of the input parameters to your optimization calculations are in a state of almost constant change and the right process controls need to be in place to stay on top of your inventories, especially the closer you get to optimal levels.

If done well, inventory optimization can transform how well your supply chain functions, but this requires a clear understanding of what it can do and how to use it. Year one of a well-designed programme can easily deliver double digit improvements from some of the easiest steps, while those who want to get much closer to optimization can deliver that type of improvement for many years in succession.

To take advantage of inventory optimization you need two things. Firstly, the ability to run the optimization calculations. Secondly, and no less importantly, the ability to operationalize the findings of your analytics. You will only sustainably improve inventory levels if your organisation can use the insights generated by the analytics in its day to day work.

The biggest value in inventory optimization analytics comes from the visibility it gives you into where the biggest opportunities for improvement are. It highlights things that are not necessarily obvious or intuitive. In the first instance, a calculation using a number of approximations is normally good enough. Once this is well understood, you can go further and seek to remove or refine the input approximations one at a time, noting that you will never remove all of them entirely.

Because the analytical challenge is high, specialist skills are required to do it properly. But those skills are not necessarily the same ones required to make changes to how your business actually works. Too much emphasis on analytics, or a siloed mentality, can leave a large gap between theory and practice. The analytics itself is only one part of the picture. In addition, you need to build the people, processes and systems to take advantage of it.

Inventory optimization is not something you can implement and then forget about. Rather, it is an ongoing process which needs constant attention. All of the input parameters to your optimization calculations are in a state of almost constant change and the right process controls need to be in place to stay on top of your inventories, especially the closer you get to optimal levels.

If done well, inventory optimization can transform how well your supply chain functions, but this requires a clear understanding of what it can do and how to use it. Year one of a well-designed programme can easily deliver double digit improvements from some of the easiest steps, while those who want to get much closer to optimization can deliver that type of improvement for many years in succession.

Would you like to take your inventory optimization to the next level?

Would you like to receive more content like this, direct to your inbox? We publish white papers on a range of supply chain topics approximately once every one to two months. Subscribe below and we will notify you of new content. Unsubscribe at any time.

Would you like to talk to one of our experts? Contact us