Cover uncovered

How retiring a metric could help improve your inventory management

Cover has a beguiling simplicity to it. Inventory cover tells you how much stock you’ve got, using a metric that makes good intuitive sense. If you have two weeks’ cover, then you know that you shouldn’t run out of inventory for two weeks.

Cover = Stock held / stock required over time period

Unfortunately, like most things in supply chain, it isn’t that simple. Cover as a metric is at best misleading and at worst positively detrimental to inventory optimization. In this white paper, we’ll look at why this is so, and what better alternatives you have.

The five (main) problems with cover

1. Uncertainty

How do you calculate the stock required? For cover to genuinely represent how many days’ worth of inventory you hold, you would need to know what future demand is going to be. Assuming your ability to predict the future is less than perfect, this will not be the case. Cover can be wildly wrong.

To calculate the stock required, you can either use historical consumption/sales, or you can use your forecast. Forecasts are generally to be avoided, since then your cover figures bake in any forecast biases you have, but using history can also be problematic, especially when you know that the future will be very different from the past.

In volatile times like those created by the Coronavirus pandemic, where past demand is a worse guide to future requirements than usual, this issue is especially evident. Where you have poor forecastability, cover is particularly meaningless as a concept since you simply don’t know how long inventory might last. Good forecasters know how to differentiate between what can be forecast well and what cannot. Unfortunately, cover mixes both together.

2. Instability

The denominator in your cover equation (the stock required) is subject to constant change, even if you use historical figures. Using longer time periods to calculate average demand can reduce noise, but is less useful for items with growing or declining demand.

This instability creates very practical headaches for those trying to calculate cover. It also makes the cover metric itself opaque, since changes in cover could be driven by the numerator or the denominator.

3. Distraction

The net impact of the two previous problems is that cover distracts attention away from actual inventory levels. Cover figures can be misleading. Consider the following example for the last ten months at a manufacturing company:

How do you calculate the stock required? For cover to genuinely represent how many days’ worth of inventory you hold, you would need to know what future demand is going to be. Assuming your ability to predict the future is less than perfect, this will not be the case. Cover can be wildly wrong.

To calculate the stock required, you can either use historical consumption/sales, or you can use your forecast. Forecasts are generally to be avoided, since then your cover figures bake in any forecast biases you have, but using history can also be problematic, especially when you know that the future will be very different from the past.

In volatile times like those created by the Coronavirus pandemic, where past demand is a worse guide to future requirements than usual, this issue is especially evident. Where you have poor forecastability, cover is particularly meaningless as a concept since you simply don’t know how long inventory might last. Good forecasters know how to differentiate between what can be forecast well and what cannot. Unfortunately, cover mixes both together.

2. Instability

The denominator in your cover equation (the stock required) is subject to constant change, even if you use historical figures. Using longer time periods to calculate average demand can reduce noise, but is less useful for items with growing or declining demand.

This instability creates very practical headaches for those trying to calculate cover. It also makes the cover metric itself opaque, since changes in cover could be driven by the numerator or the denominator.

3. Distraction

The net impact of the two previous problems is that cover distracts attention away from actual inventory levels. Cover figures can be misleading. Consider the following example for the last ten months at a manufacturing company:

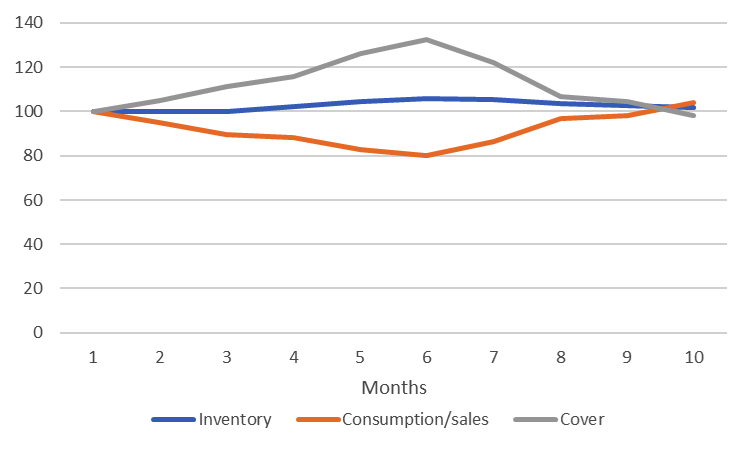

(Inventory, consumption and cover are each based at 100 in month 1. This uses a rolling 3-month average.)

Look at cover. It increases by more than 30% over 6 months, before dropping by around the same amount in the following 4 months. But the inventory itself is almost flat, deviating a maximum of 6% from its starting point. The consumption line shows us what has driven this divergence: cover increased because demand dropped, not because inventories grew.

In one sense this is fair enough. With dropping demand, you do indeed need less to cover you for longer. However, this raises the question of how useful the cover metric is. If you imagine the graph above with only the cover showing and the other two lines hidden, you would not know whether the cover represented a dip in demand and stable inventories, or stable demand and a surge in inventories.

Cover is at least one degree removed from useful measures. Planners work with units, Finance measures in cash. Cover is not a good proxy for either. Discussions of cover need to dig back into the underlying metrics to understand what is going on and what needs doing.

4. Inconsequence

How much cover do you need? Here, cover as a metric falls down on two counts. Firstly, because it is an average, it gives you no indication of how likely you are to be long or short in anything. You can have high cover and high shortages simultaneously, which perhaps more than anything else indicates how misleading the very term cover is. Secondly, it is impossible to say how much cover you really need. Unlike a service level of 95%, which gives you some sense of how well you’re doing, cover of, say, 4 weeks is quite unanchored.

5. Value destruction

Because of the previous four problems, cover risks creating and perpetuating value-destroying ways of thinking about inventory:

In one sense this is fair enough. With dropping demand, you do indeed need less to cover you for longer. However, this raises the question of how useful the cover metric is. If you imagine the graph above with only the cover showing and the other two lines hidden, you would not know whether the cover represented a dip in demand and stable inventories, or stable demand and a surge in inventories.

Cover is at least one degree removed from useful measures. Planners work with units, Finance measures in cash. Cover is not a good proxy for either. Discussions of cover need to dig back into the underlying metrics to understand what is going on and what needs doing.

4. Inconsequence

How much cover do you need? Here, cover as a metric falls down on two counts. Firstly, because it is an average, it gives you no indication of how likely you are to be long or short in anything. You can have high cover and high shortages simultaneously, which perhaps more than anything else indicates how misleading the very term cover is. Secondly, it is impossible to say how much cover you really need. Unlike a service level of 95%, which gives you some sense of how well you’re doing, cover of, say, 4 weeks is quite unanchored.

5. Value destruction

Because of the previous four problems, cover risks creating and perpetuating value-destroying ways of thinking about inventory:

- That good inventory levels are only a matter of planning to forecast

- That good inventory levels can be defined in terms of cover (rather than in absolute terms – units and value – of cycle stock and safety stock)

- That current cover levels are more or less ideal, since there is no obvious anchor to anything else – how much cover “should” you have? Using cover will tend to perpetuate the status quo

Cover is often, inappropriately, used to justify more inventories when sales rise. While a drop in sales justifies why cover has increased. It demands improved forecasting even when forecastablity is low. You know this is happening when bad forecasts are usually blamed for inventory levels and when high efforts are put into measuring forecast accuracy. Advanced companies rather look at forecastability and the value add of forecasts.

Given the problems with cover outlined above, what are some better alternatives to track and drive improvement in inventory levels?

Given the problems with cover outlined above, what are some better alternatives to track and drive improvement in inventory levels?

Three better alternatives to cover

1. At a high level, use DIO

For the highest-level aggregate inventory KPI, use Days Inventory Outstanding (DIO) instead of cover. DIO suffers from some of the same weaknesses as cover – it is a ratio rather than an absolute measure and it is unanchored – but it has the big advantages that the denominator (cost of sales) is clearly defined, makes aggregation across items simple, and is a metric already recognised by Finance. No work is needed to bridge the gap to financial reports. Of course, cost of sales also varies month to month, so we recommend only using DIO over longer time periods to look at longer-term trends: perhaps only yearly; at most quarterly, and even then comparing year on year figures.

2. At an operational management level, use inventory value

DIO is not so useful operationally, where weekly planning cycles are more common. Here we recommend using absolute inventory value as the key metric. Target safety stock and cycle stock should be calculated item by item and then rolled up into an aggregate. This then allows the gap between target and actual to be calculated on a weekly basis. In this context, “target” should not be understood as the output of weekly planning cycles, but as the output of analysis carried out over longer periods: yearly is normally a good starting point, although 6-monthly or quarterly target setting should be considered by more mature organisations. This whole process should be aligned with the monthly S&OP cycle so that expected fluctuations (allowances for seasonality, new product introduction, planned production shut downs, etc.) can be built into the longer-term plans.

3. At a planning level, balance service level and cash

At a detailed planning level, the two guiding measures should become service level and cash: finding the right balance to keep service level at or above target and inventory tied up in cash at or below target. To achieve this, and constantly improve on it, inventory needs to be segmented and the various inventory levers optimised. Focusing on the absolute requirements for cycle and safety stock at an individual item level, rather than thinking about cover in terms of days across material groups, is a powerful driver of improvement. Inventory targets and planning should be done bottom-up at an item level, not top-down at a material group level.

For the highest-level aggregate inventory KPI, use Days Inventory Outstanding (DIO) instead of cover. DIO suffers from some of the same weaknesses as cover – it is a ratio rather than an absolute measure and it is unanchored – but it has the big advantages that the denominator (cost of sales) is clearly defined, makes aggregation across items simple, and is a metric already recognised by Finance. No work is needed to bridge the gap to financial reports. Of course, cost of sales also varies month to month, so we recommend only using DIO over longer time periods to look at longer-term trends: perhaps only yearly; at most quarterly, and even then comparing year on year figures.

2. At an operational management level, use inventory value

DIO is not so useful operationally, where weekly planning cycles are more common. Here we recommend using absolute inventory value as the key metric. Target safety stock and cycle stock should be calculated item by item and then rolled up into an aggregate. This then allows the gap between target and actual to be calculated on a weekly basis. In this context, “target” should not be understood as the output of weekly planning cycles, but as the output of analysis carried out over longer periods: yearly is normally a good starting point, although 6-monthly or quarterly target setting should be considered by more mature organisations. This whole process should be aligned with the monthly S&OP cycle so that expected fluctuations (allowances for seasonality, new product introduction, planned production shut downs, etc.) can be built into the longer-term plans.

3. At a planning level, balance service level and cash

At a detailed planning level, the two guiding measures should become service level and cash: finding the right balance to keep service level at or above target and inventory tied up in cash at or below target. To achieve this, and constantly improve on it, inventory needs to be segmented and the various inventory levers optimised. Focusing on the absolute requirements for cycle and safety stock at an individual item level, rather than thinking about cover in terms of days across material groups, is a powerful driver of improvement. Inventory targets and planning should be done bottom-up at an item level, not top-down at a material group level.

Conclusions

Cover is still a very common supply chain metric. It has the benefit of familiarity. And it reflects an intuitive understanding that the amount of inventory you need is not unrelated to expected demand. Where cover is used it should not be abandoned overnight. Instead, it is worth keeping cover in place while the organisation gets used to the better measures proposed here, before being gently retired.

But, for the reasons outlined in this paper, the known weaknesses of cover as a metric can be positively detrimental to the way you think about inventory. To become truly world-class in inventory management you need to move away from cover.

But, for the reasons outlined in this paper, the known weaknesses of cover as a metric can be positively detrimental to the way you think about inventory. To become truly world-class in inventory management you need to move away from cover.

Would you like to receive more content like this, direct to your inbox? We publish white papers on a range of supply chain topics approximately once every one to two months. Subscribe below and we will notify you of new content. Unsubscribe at any time.

Would you like to talk to one of our experts? Contact us