De-risking key component supply for a manufacturer

Our client was concerned about its reliance on a small number of suppliers for a key class of components in its manufacturing process. It engaged nVentic to help it consider and quantify strategic alternatives in order to reach an objective decision and develop a multi-year roadmap.

Context

The component was a mature technology, but increasing market requirements indicated that the current material solutions, even though necessary in the short term, might prove inadequate over time. Our client was heavily reliant on a small number of suppliers, which represented an unacceptable concentration risk.

nVentic was engaged to:

The component was a mature technology, but increasing market requirements indicated that the current material solutions, even though necessary in the short term, might prove inadequate over time. Our client was heavily reliant on a small number of suppliers, which represented an unacceptable concentration risk.

nVentic was engaged to:

- Identify and consider all strategic alternatives

- Develop a properly weighted decision-making process

- Find a solution that reduced the risk represented by the existing supply base, improved energy efficiency and minimized total cost of ownership

- Create a roadmap to move to the identified optimal solution as rapidly as necessary

Approach

nVentic started by baselining the starting situation:

nVentic started by baselining the starting situation:

- There was only one material solution in full operation

- The existing low-cost supply base represented a major risk, with both our client and its primary supplier very heavily reliant on each other

- The existing solution had known issues relative to corrosion, wear, performance, cost and size

- Evolving market requirements indicated that the limits of the existing technology were being reached

- Supply alternatives were much more costly and less flexible

- Two main material alternatives existed, but each with its own risks due to the fact they were untested and would in addition require process changes, some extensive

- In-house technical knowledge was limited to the existing material. The adoption of alternative materials would necessitate a significantly longer timeline

Pricing of the different technical alternatives was compared, including projected price developments over the coming 5 years. We baselined our client’s existing exposure to each supplier.

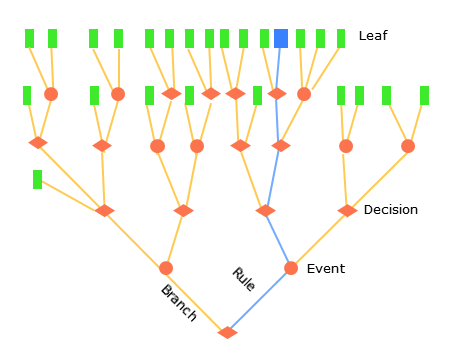

Once the different alternatives were fully identified and described, nVentic led a structured methodology to develop an optimal path. Some of the principle tools used included:

Once the different alternatives were fully identified and described, nVentic led a structured methodology to develop an optimal path. Some of the principle tools used included:

- Decision trees

- Failure Mode and Effects Analysis (FMEA), including financial impact and risk

- Scenario analysis

A decision tree

For the FMEA and scenario analyses, worst-case scenarios such as the complete and unannounced failure of the biggest supplier were quantified.

On the basis of all analyses, a business case was created to offset the mitigation costs against the weighted risk costs.

Results

Using a weighted scorecard, an alternative material was identified as the optimal solution over the longer term. Some of the principal reasons for this were superior performance, especially for new market demands, greater design flexibility, patent protection, compactness, and independence from unreliable suppliers. However, this was not a viable short-term solution.

Following the completion of all analyses, a multi-phased roadmap was developed. The strategy recommended and subsequently adopted had two main strands:

On the basis of all analyses, a business case was created to offset the mitigation costs against the weighted risk costs.

Results

Using a weighted scorecard, an alternative material was identified as the optimal solution over the longer term. Some of the principal reasons for this were superior performance, especially for new market demands, greater design flexibility, patent protection, compactness, and independence from unreliable suppliers. However, this was not a viable short-term solution.

Following the completion of all analyses, a multi-phased roadmap was developed. The strategy recommended and subsequently adopted had two main strands:

- Vertical supply chain integration of the main supplier

- Accelerated development of alternative material solutions

The roadmap set out a phased plan for the following three years. Year one focused on de-risking the existing situation as much as possible while continuing tests of alternative materials, years two and three concentrated on the ramp-up of alternative technical solutions.

The outcome of the project was the elimination of our client’s principal supply risk and the protection of a significant percentage of EBIT.

The outcome of the project was the elimination of our client’s principal supply risk and the protection of a significant percentage of EBIT.

Would you like to talk to one of our experts? Contact us